1、機(jī)器人編碼器上數(shù)據(jù)存儲的電池?zé)o電或者已經(jīng)損壞拆卸編碼器脈沖數(shù)據(jù)存儲的電池安裝盒,對電池盒每節(jié)電池的電壓進(jìn)行測量,均在1.4V以下,電池電壓明顯偏低,更換新電池,再對故障進(jìn)行復(fù)位。

1. The battery for data storage on the robot encoder is dead or damaged. Remove the battery installation box for encoder pulse data storage and measure the voltage of each battery in the battery box, which is below 1.4V. The battery voltage is significantly low. Replace the battery with a new one and reset the fault.

2、控制器內(nèi)伺服放大器控制板出故障,檢查伺服放大器LED上方的2個(gè)DC鏈路電壓檢測螺絲,確認(rèn)DC鏈路電壓。如電壓高于50V,伺服放大器控制板處于異常狀態(tài)。電壓低于50V,可初步判斷處于正常狀態(tài)。進(jìn)一步對伺服放大器控制板的LED顏色進(jìn)行觀察,確認(rèn)電源電壓輸出正常,沒有外部緊急停止信號輸入,與機(jī)器人主板通信正常可排除伺服放大器控制板損壞。

2. The servo amplifier control board in the controller has malfunctioned. Check the two DC link voltage detection screws above the servo amplifier LED to confirm the DC link voltage. If the voltage is higher than 50V, the servo amplifier control board is in an abnormal state. If the voltage is below 50V, it can be preliminarily judged that it is in a normal state. Further observation of the LED color on the servo amplifier control board confirms that the power voltage output is normal, there is no external emergency stop signal input, and communication with the robot motherboard is normal, which can rule out damage to the servo amplifier control board.

3、線路損壞對機(jī)器人控制器與機(jī)器人本體的外部電纜連線RM1、RP1進(jìn)行檢查,RM1為機(jī)器人伺服電機(jī)電源、抱閘控制線,RP1為機(jī)器人伺服電機(jī)編碼器信號以及控制電源線路、末端執(zhí)行器線路和編碼器上數(shù)據(jù)存儲的電池線路等線路。拔掉插頭,對編碼器上數(shù)據(jù)存儲的電池線路進(jìn)行檢查。拔掉M1電機(jī)的脈沖控制插頭M1P,同樣的方法檢查M2~M7電機(jī)全部為0,可判斷編碼器上數(shù)據(jù)存儲的電池線路損壞。

3. Inspect the external cable connections RM1 and RP1 between the robot controller and the robot body for damaged wiring. RM1 represents the power supply and brake control line of the robot servo motor, RP1 represents the signal of the robot servo motor encoder, as well as the control power supply line, end effector line, and battery line for data storage on the encoder. Unplug and check the battery circuit for data storage on the encoder. Unplug the pulse control plug M1P of the M1 motor and use the same method to check that all motors from M2 to M7 are 0, which can indicate that the battery circuit for data storage on the encoder is damaged.

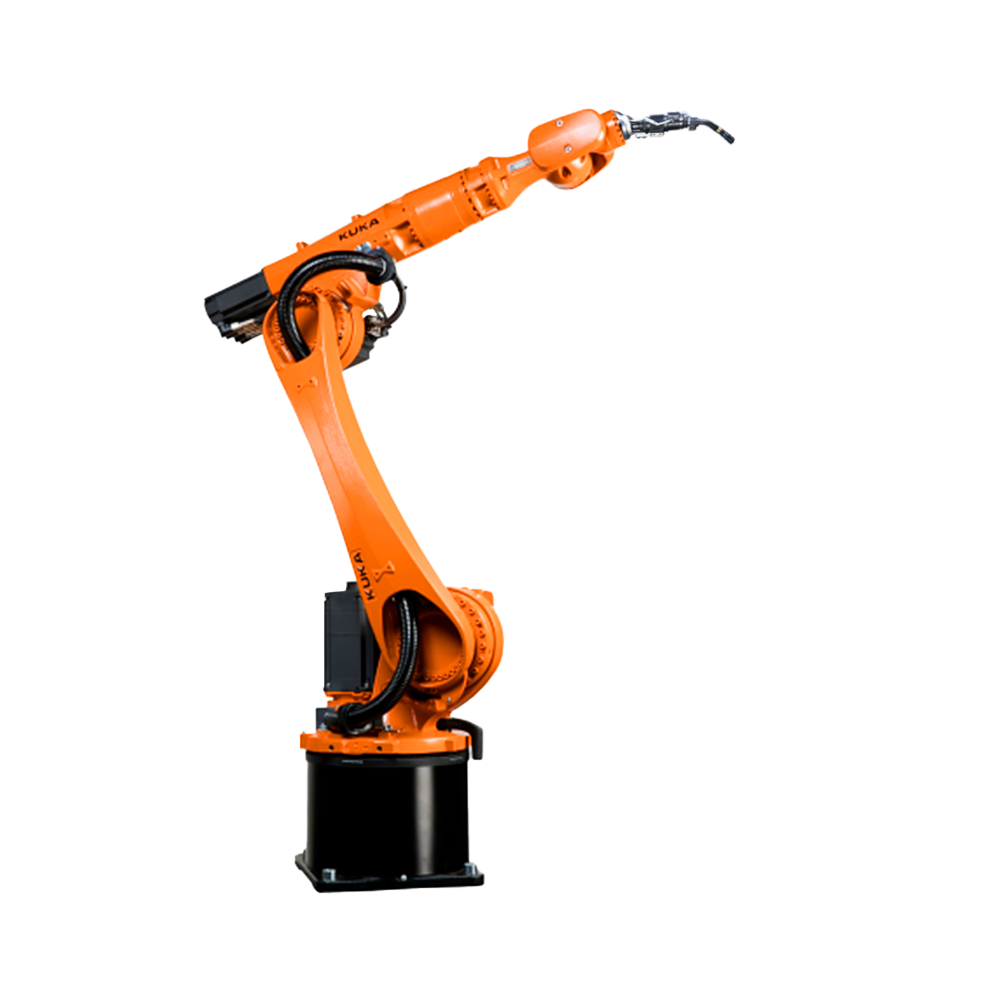

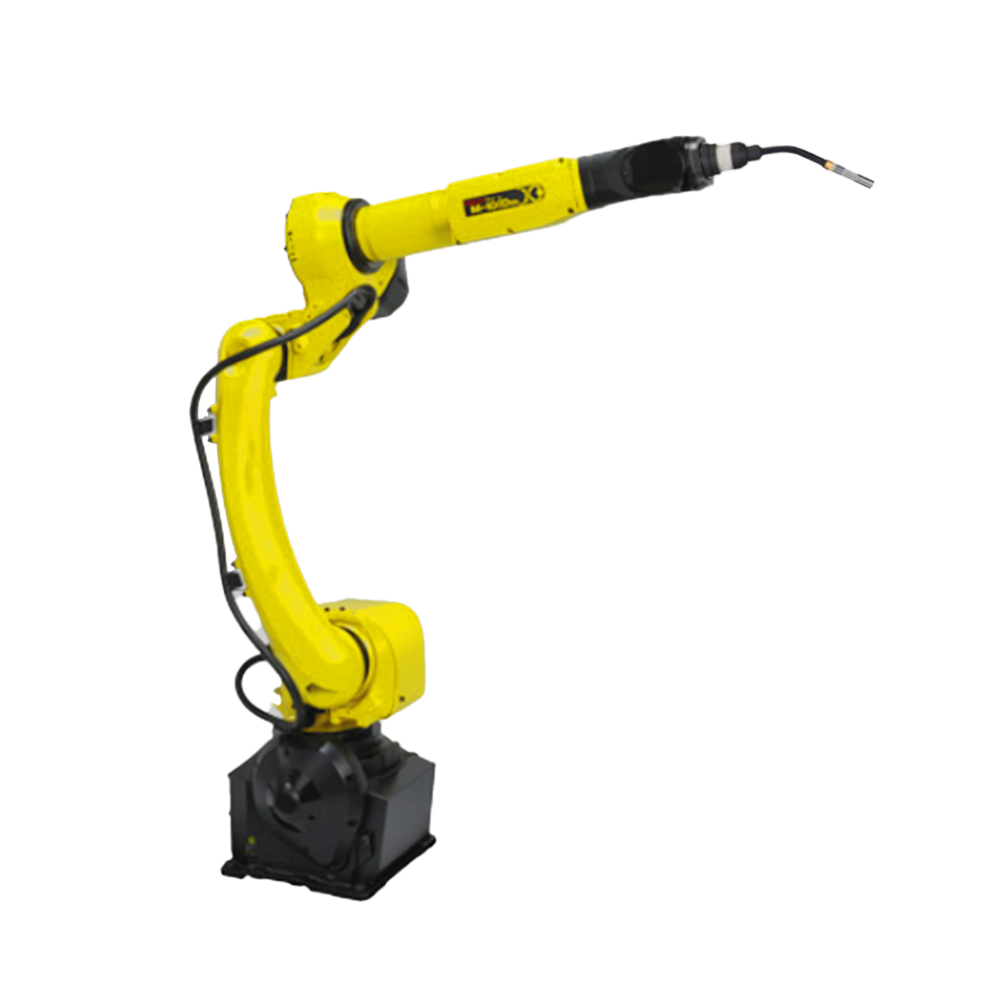

機(jī)器人編程技巧:

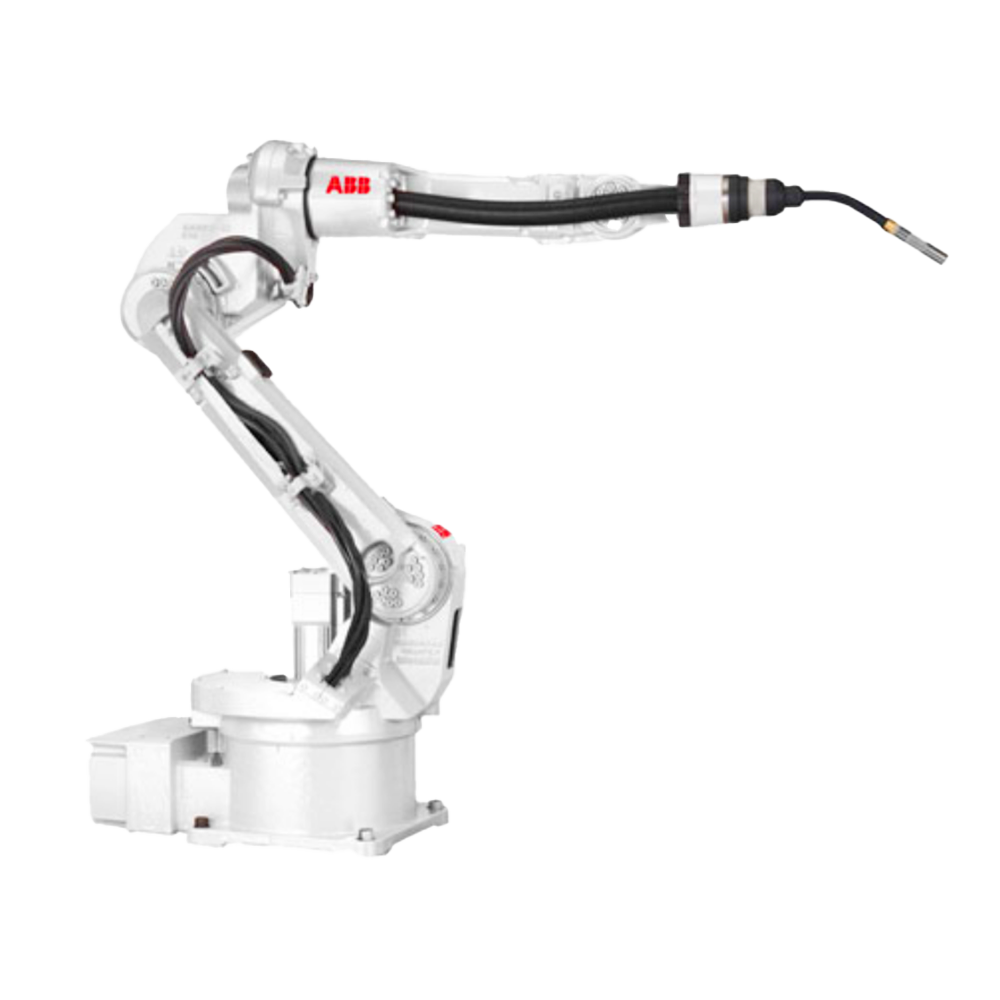

Robot programming skills:

(1)選擇合理的焊接順序。以減小焊接變形、焊槍行走路徑長度來制定焊接順序。

(1) Choose a reasonable welding sequence. Develop welding sequence to reduce welding deformation and the length of welding gun travel path.

(2)焊槍空間過渡要求移動(dòng)軌跡較短、平滑、。

(2) The space transition of the welding gun requires a short, smooth, and safe movement trajectory.

(3)優(yōu)化焊接參數(shù)。為了獲得佳的焊接參數(shù),制作工作試件進(jìn)行焊接試驗(yàn)和工藝評定。

(3) Optimize welding parameters. In order to obtain optimal welding parameters, work specimens are made for welding tests and process evaluation.

(4)合理的變位機(jī)位置、焊槍姿態(tài)、焊槍相對接頭的位置。工件在變位機(jī)上固定之后,若焊縫不是理想的位置與角度,就要求編程時(shí)不斷調(diào)整變位機(jī),使得焊接的焊縫按照焊接順序逐次達(dá)到水平位置,同時(shí),要不斷調(diào)整機(jī)器人各軸位置,合理地確定焊槍相對接頭的位置、角度與焊絲伸出長度。工件的位置確定之后,焊槍相對接頭的位置通過編程者的雙眼觀察,難度較大。這就要求編程者善于總結(jié)積累經(jīng)驗(yàn)。

(4) Reasonable positioning of the positioner, welding gun posture, and the relative position of the welding gun to the joint. After the workpiece is fixed on the positioning machine, if the weld seam is not in the ideal position and angle, it is required to continuously adjust the positioning machine during programming, so that the welded weld seam reaches the horizontal position one by one according to the welding sequence. At the same time, the position of each axis of the robot should be continuously adjusted to reasonably determine the position, angle, and wire extension length of the welding gun relative to the joint. After determining the position of the workpiece, the position of the welding gun relative to the joint is difficult to observe with the programmer's eyes. This requires programmers to be good at summarizing and accumulating experience.

(5)及時(shí)插入清槍程序。編寫一定長度的焊接程序后,應(yīng)及時(shí)插入清槍程序,可以防止焊接飛濺堵塞焊接噴嘴和導(dǎo)電嘴,保證焊槍的清潔,提高噴嘴的壽命,確保可靠引弧、減少焊接飛濺。

(5) Insert the gun cleaning program in a timely manner. After writing a certain length of welding program, the cleaning program should be inserted in a timely manner to prevent welding spatter from blocking the welding nozzle and conductive nozzle, ensuring the cleanliness of the welding gun, improving the lifespan of the nozzle, ensuring reliable arc ignition, and reducing welding spatter.

(6)編制程序一般不能一步到位,要在機(jī)器人焊接過程中不斷檢驗(yàn)和修改程序,調(diào)整焊接參數(shù)及焊槍姿態(tài)等,才會形成一個(gè)好程序。

(6) Programming generally cannot be done in one step, and it is necessary to continuously inspect and modify the program, adjust welding parameters and gun posture during the robot welding process, in order to form a good program.