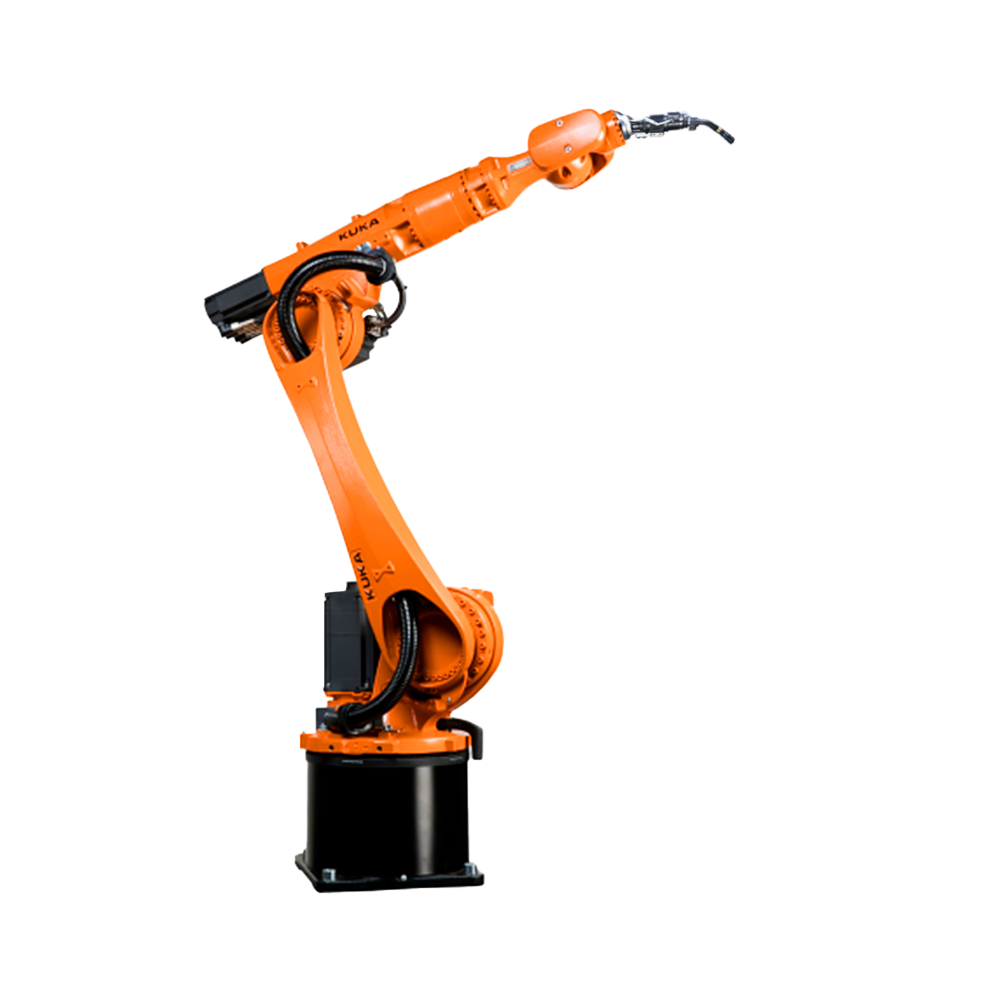

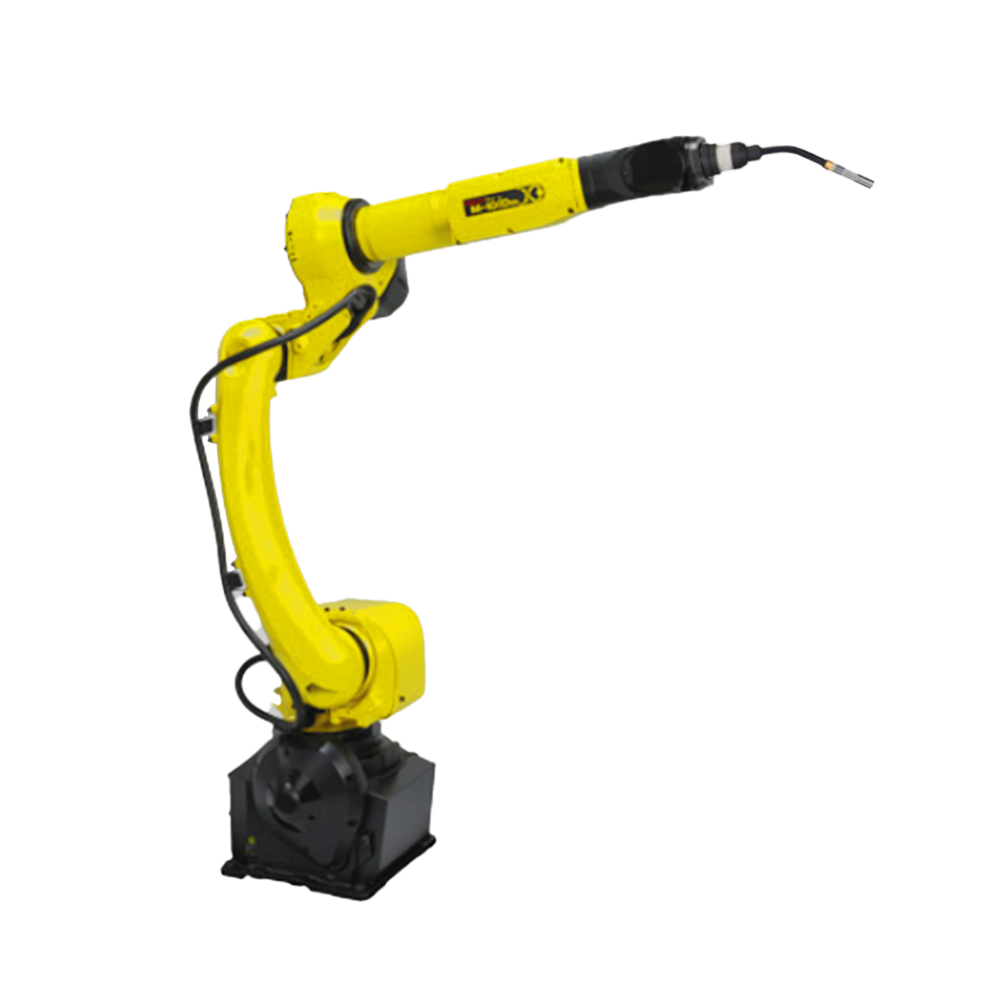

自動(dòng)化焊接機(jī)械的優(yōu)點(diǎn)

The advantages of automated welding machinery

(1)生產(chǎn)效率高。埋弧焊可以使用較大的電流,電弧的穿透能力較強(qiáng),焊縫熔深大。埋弧焊熱量集中,焊接速度快,生產(chǎn)效率比手工電弧焊提高5-10倍。

(1) High production efficiency. Submerged arc welding can use larger currents, with stronger arc penetration ability and greater weld penetration depth. Submerged arc welding has concentrated heat, fast welding speed, and production efficiency that is 5-10 times higher than manual arc welding.

(2)焊接質(zhì)量高而且穩(wěn)定。焊接規(guī)范可自動(dòng)控制調(diào)整,保持穩(wěn)定。焊劑保護(hù)效果好,防止空氣對(duì)熔池金屬的侵害。加上電流大,熔池金屬與渣反應(yīng)充分,使其成分均勻。埋弧焊焊縫金屬質(zhì)量高,性能穩(wěn)定,且外表成形美觀。

(2) The welding quality is high and stable. Welding specifications can be automatically controlled and adjusted to maintain stability. The flux has a good protective effect, preventing air from damaging the molten pool metal. Combined with high current, the metal in the molten pool reacts fully with the slag, making its composition uniform. The submerged arc welding seam has high metal quality, stable performance, and aesthetically pleasing appearance.

(3)節(jié)省材料和電能消耗。電弧在焊劑層下燃燒,熱量的散失減少,消耗的電能也就減少。另外,中薄板焊接時(shí)可以不開坡口,焊絲金屬?zèng)]有飛濺損失,沒有焊條頭,所以能節(jié)省大量焊接金屬材料。

(3) Save material and electricity consumption. The arc burns under the flux layer, reducing the loss of heat and consuming less electrical energy. In addition, when welding medium and thin plates, there is no need to make grooves, and the welding wire metal does not have splashing loss or welding rod head, so a large amount of welding metal materials can be saved.

(4)改善勞動(dòng)條件,降低勞動(dòng)強(qiáng)度。因?yàn)殡娀≡诤竸酉氯紵附訒r(shí)看不見弧光,焊接煙霧也很小,所以,勞動(dòng)條件得到很大的改善。

(4) Improve working conditions and reduce labor intensity. Because the arc burns under the flux layer, the arc light cannot be seen during welding, and the welding smoke is also very small, so the working conditions have been greatly improved.

(5)由于埋弧焊焊接時(shí),電弧區(qū)不可見,因此對(duì)接頭的加工和工件裝配要求嚴(yán)格。埋弧自動(dòng)焊一般要求在平焊位置進(jìn)行焊接,對(duì)于位置狹窄的焊縫及薄板焊縫,采用埋弧焊有一定的困難。

(5) Due to the invisible arc zone during submerged arc welding, strict requirements are placed on the processing of joints and the assembly of workpieces. Automatic submerged arc welding generally requires welding to be carried out in the flat welding position. For narrow position welds and thin plate welds, using submerged arc welding has certain difficulties.

本文由自動(dòng)化焊接機(jī)械54友情奉獻(xiàn)。更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.umean.cn/真誠(chéng)的態(tài)度為您提供為的服務(wù),更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn),敬請(qǐng)期待。

This article is a friendly contribution from 54 automated welding machinery. For more information, please click on: http://www.umean.cn/ Sincere attitude will provide you with excellent service, and we will gradually contribute more relevant knowledge to everyone. Stay tuned.